An exploration focused on maximizing the use case of a utility blade, in this partner-ed project we looked at prioritizing maximum utility, minimizing footprint, and optimizing ergonomics for multiple use cases.

Duration: 15 Weeks

Role: Co-lead Industrial Designer

Credits: Raphael Abel, Kim Sherman (Mentor)

Arrow

Reimaging a utility knife

State of the Art

Multi tools consider users' daily tasks, not how they actually perform them.

We surveyed 34 designers and engineers and discovered that many people only use X-Actos because better options for precision are limited.

What is your most used cutting tool?

What is your least favorite cutting tool?

Quotes from Interviews

“I do rough and precision cutting.”

“Bulky handles makes precision work difficult.”

“I'd use multi-tools if they were lightweight.”

“I use different tools for different jobs, depends what I have on me at the time.”

Product Positioning

Moodboard

CMF Strategy

Ideation & Prototyping

Features & Rationale

Offers 3x the utility of a typical disposable blade.

Made from 100% Steel

Why?

Most recycled material in the world

520 Billion dollar industry

Supports nearly 2 million jobs

Negative space for light weighting

Blade is 1/3 more narrow than a traditional box cutter blade to save material and support more precise cutting.

Material Reduction

Changing Blades

Slide blade in until notch is secured by tab.

Lift tab and pull blade out to change blade.

Lock engages when knife is open.

Push in bar while closing to release lock.

Hole fits on keychains and carabiners for added portability.

Use Cases

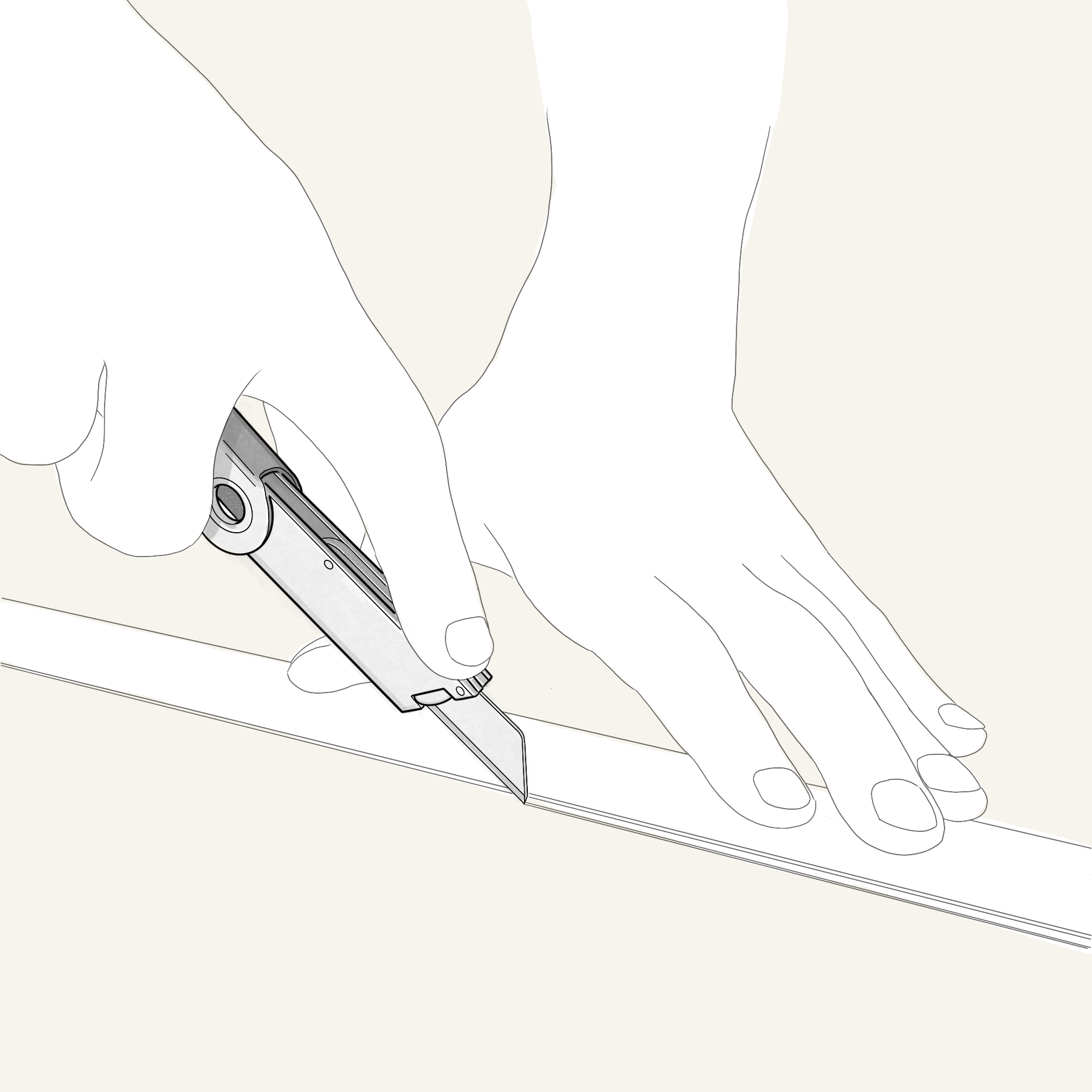

Precision Cutting

Tape Splitting

Small Rope Cutting

Small enough to fit in female pocket

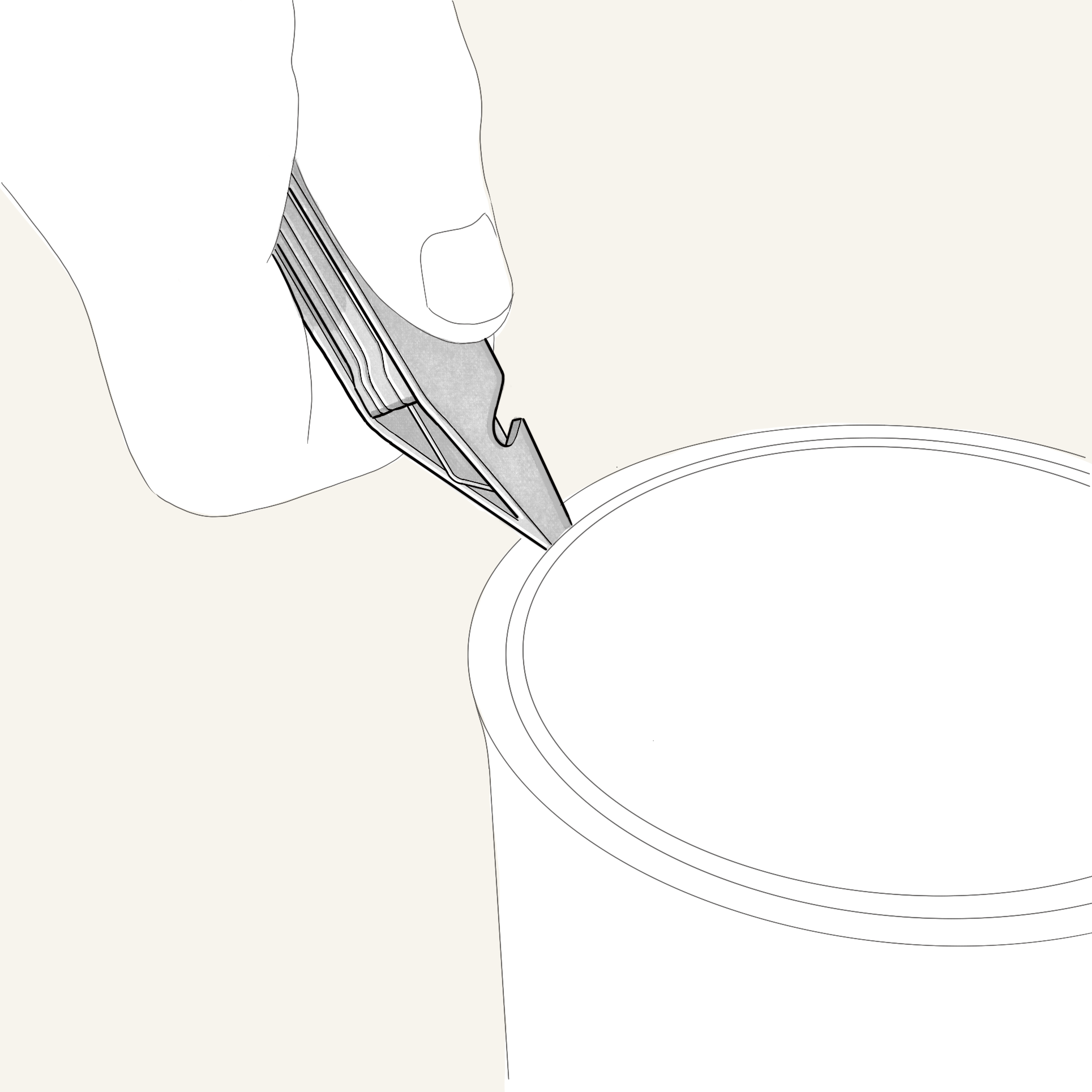

Prying Open Cans

Screwing and Unscrewing

Next Project Suggestion

The Haven

The 3-in-1 Cat Bed for a Multi-Cat Household